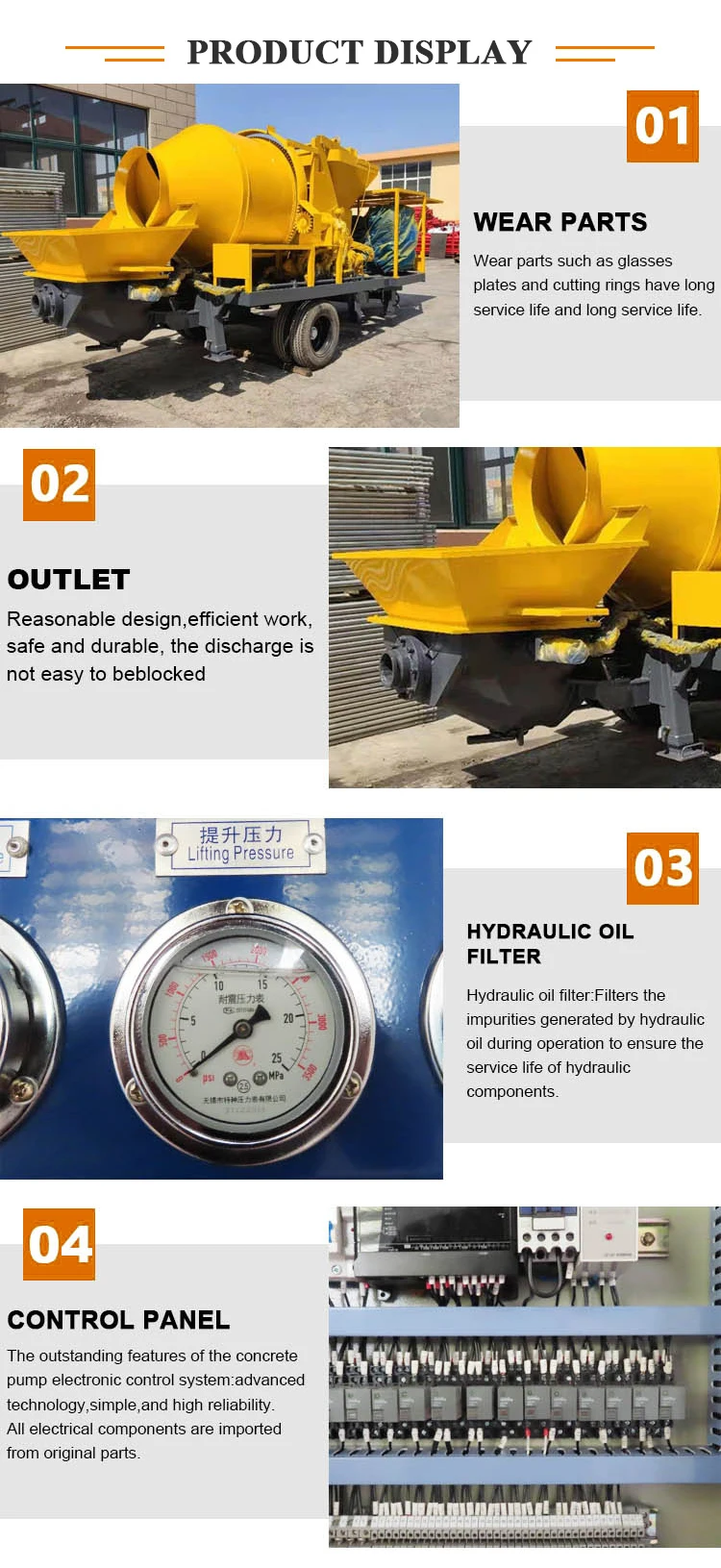

Product Details

Automobile and construction machinery manufacturers

There are many suppliers who manufacture mixer pumps in the market. You can find mixing pump suppliers online or offline. Of course, you can also look for suppliers locally or abroad. But most importantly, you need to find a reputable supplier with many good reviews from customers. Elorry Group has been focusing on the construction machinery industry for many years.